Hand Forged

Handmade Cleavers

Heavy Duty Saw Tooth Cleavers

Heavy duty cleaver.

Handmade cleaver. Hand forged from lumber mill carbon steel.

Tough and strong cleavers hand forged from recovered high carbon lumber mill saw blade steel. This modern steel was designed as a high impact, tensile steel. The Saw Tooth Cleavers have 7mm thick blades with high bevels and high impact razor edges differentially tempered for a hard edge and a tough body.

We leave the teeth on the spine for tenderizing meat.

Lumber mill saw blades are a source of knife steel stock. High quality, high carbon steel. We have been working with these steels since 1997, exclusively since 2000. There are many different blades in a lumber mill, different carbon and alloy contents. Each lending to a different tool and knife. We produce handmade, high end woodworking and woodcarving tools, hunting, survival, bushcraft, kitchen knives ulus and farrier knives.

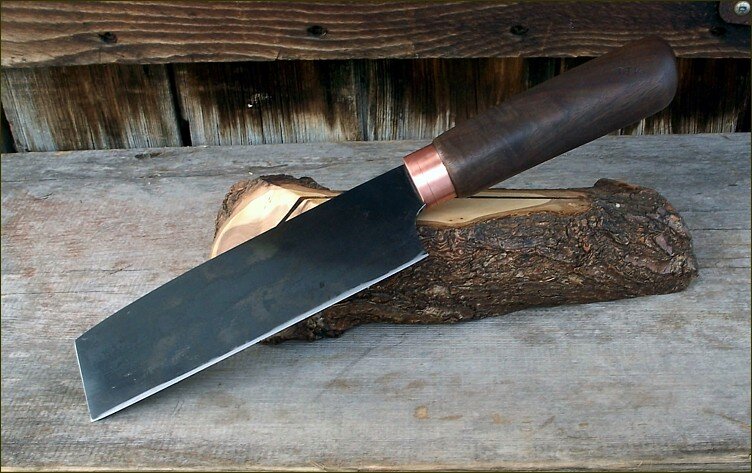

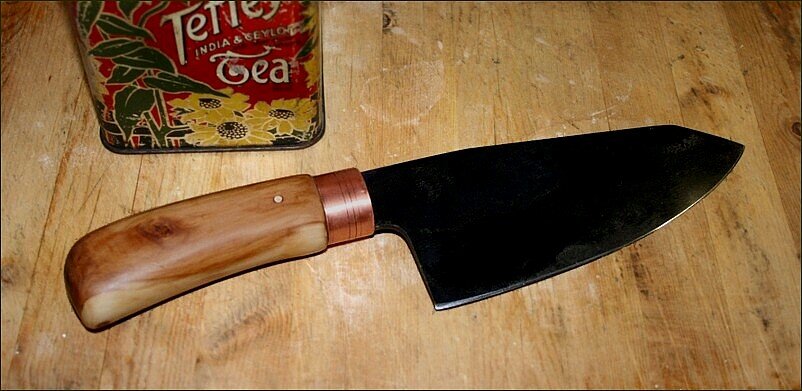

Unique Hand Forged Cleavers

The handmade saw tooth meat cleavers above have a 7 - 9 inch edge, 3/16 and 1/4 inch spines and a long 5 - 8 inch handles.

The Heavy Duty Saw Tooth Cleaver

We have a limited supply of these blades.

Carbon steel cut from a 4 foot x 1/4 inch saw blade. 7 inch edge. Forged carbon steel saw blade steel. An 8 inch edge chef knife, 3/16 inch spine. Both have moose antler scales. $3600.

“I can't begin to tell you how happy I am with my new cleaver. I did receive the cleaver in time for the bbq and it stole the attention of all who attended (no small feat considering the 16 hr smoked local grass fed beef briskets and the 12 hr smoked Berkshire pork shoulders)”. -- Head chef, Turks & Caicos

We custom design knives for customers. Working with them to make great knives that are unique, one of a kind… functional working art from material you can’t buy. Hand picked recovered materials. The idea is not to cut corners - in fact, it’s the opposite.

The Knife Shop. -39C.

We live simply and work in the bush on the edge of the Chilcotin plateau growing our food, creating art, while leaving a light footprint. Our power for the shop and cabin is from the sun. Up-cycling or recycling, re-purposing or re-using and trying not to exploit others while creating working knives and tools. With a small, efficient system we are powered by the sun’s energy. It takes time acquiring and working with these materials.